Ultra X3

Details

- Type and specification of Dunlop belt supplied

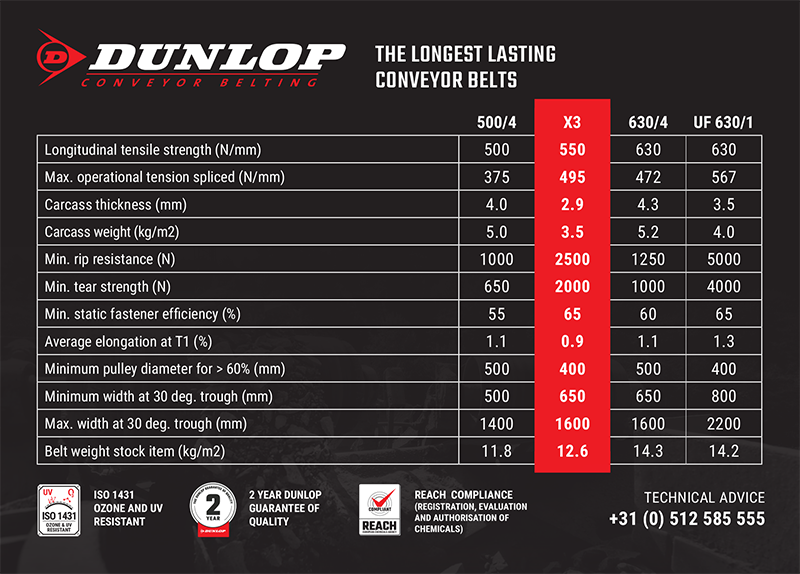

- Single-ply Dunlop X3

- Current operating life of Dunlop belt

- 14 months +

- Average life of previously installed belt – months

- 8 months

A large aggregate recycling plant in Scotland had been using 10mm thick EP500/3 belts. The conveyor is used to convey a range of aggregates from 80mm heavy rock to fine abrasive sand materials.

Six years ago a change was made to a much heavier, 5-ply construction belt because the 500/3 belts were typically only lasting for around 8 months. When it became necessary because of wear to then replace the 5-ply belt, Dunlop service partner Ace Vulcanising in Scotland advised their customer to have a single-ply Dunlop Ultra X3 6+2 belt fitted because of its considerable strengths and advantages compared to conventional multi-ply construction belting.

Now, some 14 months later, the site management team are delighted with how the Ultra X belt is performing. Despite running 12-16 hours per day Monday-Friday and 6 hours per day Saturday & Sunday, the surface of the belt is almost unmarked. Another benefit has been that the conveyor now needs less power/ torque to run the Ultra X belt as it is a lot lighter than the 5-ply. Yet another bonus has been the fact that they have not had to change any of the conveyor’s bearings or drums during this time. Although the meter price of the Ultra X belt was a little higher than the 500/3 belts, it was actually much less expensive compared to the 5-ply belt. These advantages, together with reduced maintenance costs and reduced environmental impact have proved to be yet another stand-out success for Ultra X.

Location: Scotland

Type of material carried: Aggregates - 80mm heavy rock to fine abrasive sand

Industry: Quarry