The Strongest Link – how finger splicing turns the weakest link into the strongest link

Virtually without exception, the weakest point of any conveyor belt is the splice joint. In fact, it is estimated that nearly 80% of all conveyor stoppages are caused by splice joint problems. Because of the potential loss of output, as well as the safety implications caused by splice joint failure, it is critically important to maximize the strength and long-term durability of the joint.

The most common method of making a splice joint is the step splice, which requires the removal of one of the layers of fabric plies so that the two belt ends can be overlapped and then either cold glued or hot vulcanized together. This method is popular because it is seen to be generally easier and quicker to make a step splice. However, these ‘advantages’ come at the expense of the far superior strength and reliability achieved by using the finger splice jointing method. For those who may not be familiar with the term, finger splicing is where a zigzag pattern is cut into both sides of the belt ends, creating several interlocking ‘fingers’. These are then carefully aligned, interlocked together and finally bonded using a hot vulcanizing press to make a splice that is very strong and flat.

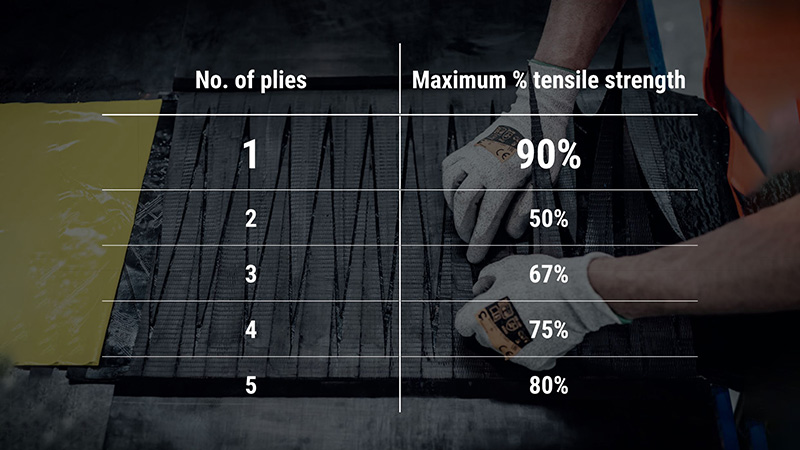

Although it is not physically possible to join a belt without some loss of longitudinal tensile strength, regardless of the method used, the biggest disadvantage of a standard step splice is that it will always create a proportional loss of tensile strength equivalent to one ply.

As can be seen in table 1, a 3-ply step joint can only achieve a maximum longitudinal tensile strength of 67%. This effectively means that in a typical multi-ply belt containing three plies or more, at least one ply exists purely to compensate for the loss of the longitudinal strength incurred by making a step splice joint. In contrast, the big advantage of the finger splice method is that it retains up to 90% of the belt’s ‘static’ tensile strength. Apart from the greater strength, this opens up the possibility of installing a lower and therefore less expensive specification such as a 630/3-ply belt instead of a 630/4-ply.

Another advantage is that, crucially, in dynamically stressed conditions when the belt is working under load, the finger splice is vastly superior to a stepped splice in terms of resistance to dynamic failure. The superior strength and durability of finger splices also reduce the frequency of repair and re-splice. These are important considerations because they can significantly reduce both direct (actual repair) and indirect (lost output) costs. For example, one quarry in the UK had been replacing splices on its multi-ply belts every three months. They were naturally delighted to discover that during the first 18 months after installing single-ply belts using the finger splice method, they had not repaired or replaced a single splice.

Although much is sometimes made of the fact it can take longer to make a good quality finger splice, this is often more of a reflection on the skill of the person actually making the splice. Skill, experience and making the best use of available tools makes a big difference. For example, dedicated templates with the finger shape predefined and ready to trace onto the belt are available which help speed up the process and greatly improve accuracy.

Templates speed up the process and improve accuracy

Ironically, templates are not available for stepped splices so the accuracy depends much more on the skill and attention of the splicer who is measuring and cutting.

Finger splices are nothing new of course. Historically, finger splicing was the favoured technique and remains the standard practice for joining solid woven belts used underground and for most fabric single-ply and dual-ply rubber belting, such as Fenner Dunlop’s hugely popular Ultra X and UsFlex range. All the evidence points to the fact that it makes no sense to try and ‘save’ a few hundred euros by opting for the less durable step splice. The perceived ‘speed and ease’ cost advantages are a small fraction of the cost of a system shutdown to carry out joint repairs or the many thousands spent buying and installing the belt in the first place.

Bob Nelson